Tverskoy verstatobudivny plant. Savelіvskiy mashinobudіvniy zavod smz, savma

“The portfolio of the construction of the Savelovsky Verstatobudivny Plant reaches 900 million rubles. Tse means a stable business venture and good prospects for development until the end of 2017, - said Vadim Sorokin, General Director of STAN LLC. - The correct organization of the management of the Maidan and the planned work of the assistants allow the plant to work rhythmically, to cry in due time. wages, taxes, social and utility payments”.

Kerіvnik TOV "STAN" said that CVD will reach the warehouse of the company "STAN" in the middle of 2016, and soon it will be included to the centralized corporate system for the promotion and cooperation. Today, CVD is concluding important contracts with the subsidiaries of the United Aircraft Corporation, State Corporation Rostec, Zokrema, preparing typesetting for the Sokil aircraft plant, PJSC Rostvertol. In addition, in cooperation with the Ivanovskoye plant, an important workbench, which also enters the STAN warehouse, CVD produces universities for technological equipment for Uralvagonzavod, appointing V. Sorokin.

In the next hour, STAN is planning on contracting CVDs to win big contracts with leading Russian companies in the amount of about 400 million rubles. There is a need to discuss the modernization of the technological equipment of JSC "Aviastar-SP" within the framework of the state program for the release of the aircraft AN-124.

A unique team and specialization in key machine-building galuzias — the avionics aerospace — strain strain — the basis for the susceptibility and caliber growth of the greater number of CVD indications in the nearest rocks, — V. Sorokin said.

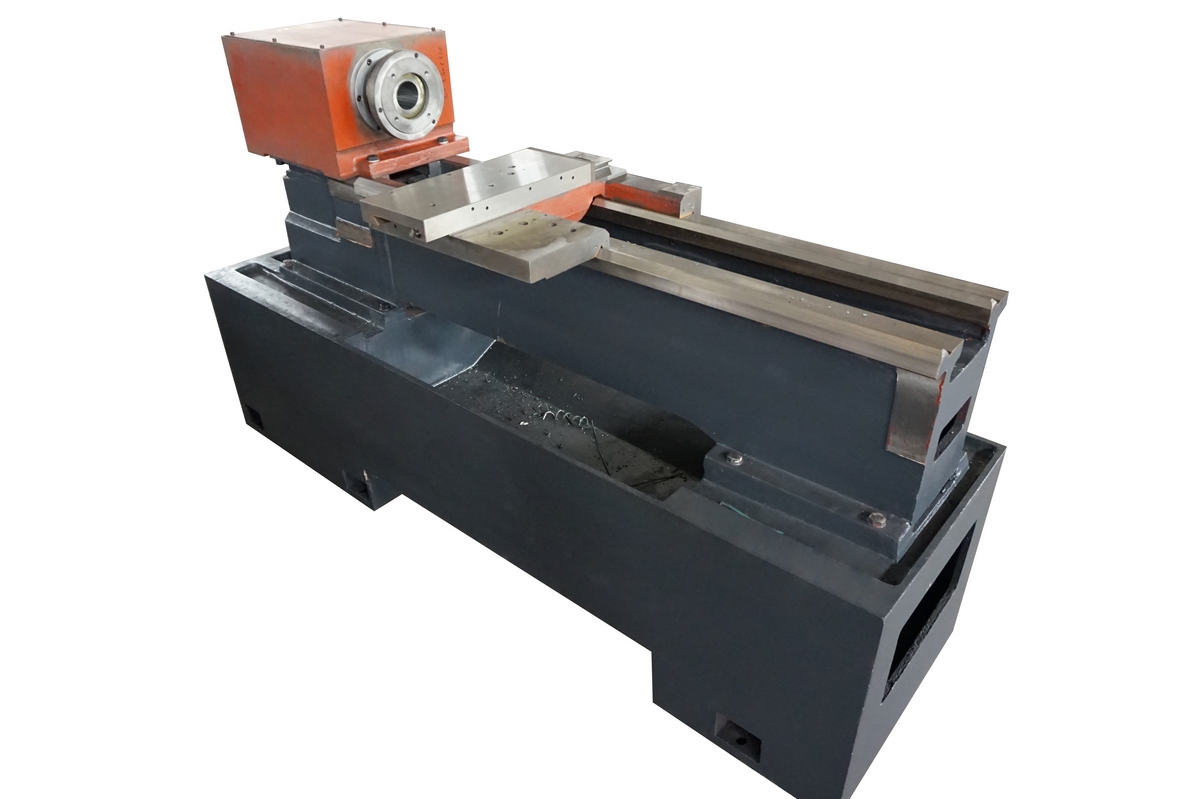

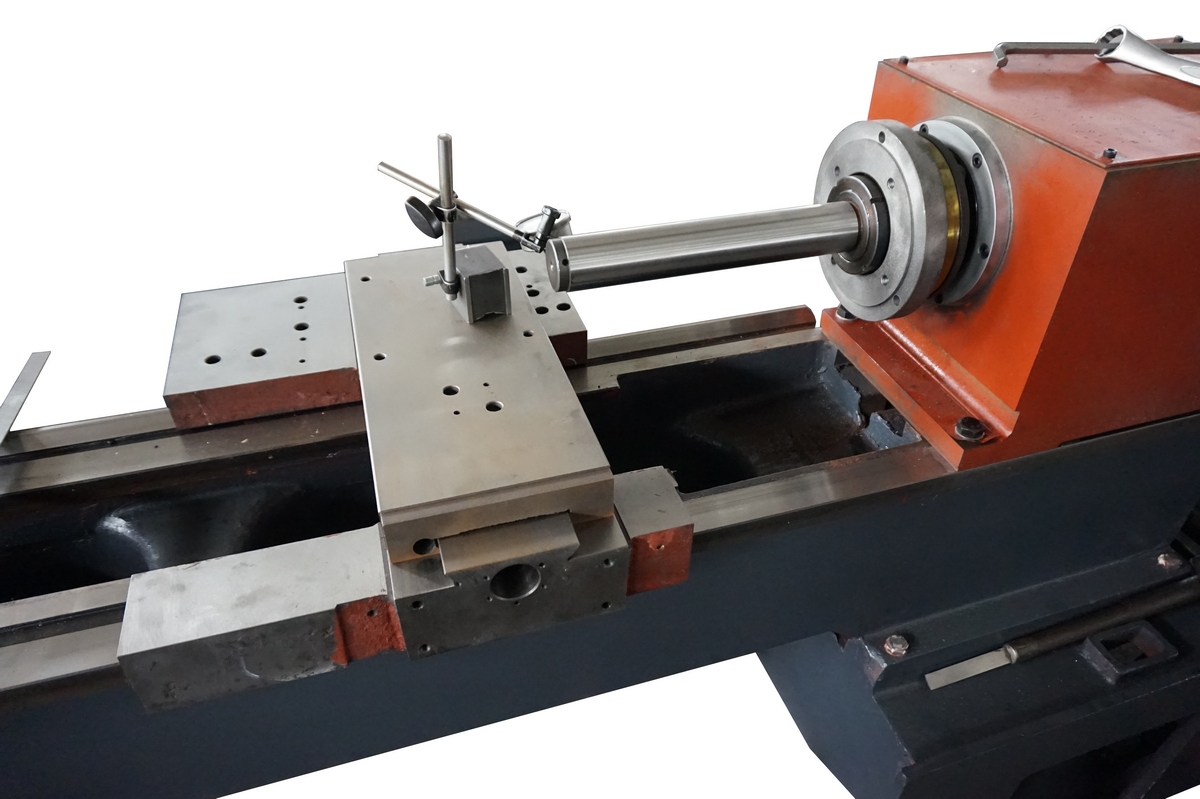

TOV "Savelovsky workbench plant"- Virobnichiy maidanchik TOV "STAN" near the metro station Kimry (Tverska region). Specializes in the production of vertical milling processing centers, portal milling benches from a ruhomomi table and special equipment.

TOV "STAN" - the largest Russian integrated company in the field of design and production of working environment, established in 2012. The company’s warehouse includes pickers in Bashkortostan (TOV NVO Stankobuduvannya, Sterlitamak metro station), Kolomna (AT Stankotekh), Ryazan (TOV Ryazansky Stankozavod), Ivanovo (TOV Ivanovsky Zavod important workbench”), Moscow (TOV “Shlifuvalni Verstati”), Tver region (TOV “Savelivskiy Verstatobudivniy Zavod”, Kimri). STAN's deputies are the Russian galuzev association, the state corporation Rostec holdings, the enterprises of PJSC "UAC", Roskosmos, Rosatom, RZ, as well as companies of the oil and gas complex. Over 50% of metalworking versativs, which are issued in Russia, fall on STAN's part.

Є TOV "STAN".

Be kind, IMPORTANTLY read the Rules for the use of materials in our resource:

RULES FOR SITE INFORMATION

burning position

The information posted on this site is considered to be only for the knowledge of non-commercial content.

The author and vlasnik of the site did not bear responsibility for possible traces vykorannya placed on new information with a method, fenced by chinny international tarussian legislation. Watching our site You should not stop spying on new information with the method, fenced by the official legislation of Ukraine.

Deyakі storіnki site can vengeance on other sites that belong to third persons. Data is posted solely for the sake of transparency and we cannot give any guarantees as to the nature of the content of these sites, the reliability and accuracy of the information posted on them, or their availability for readers.

Rules for copying and quoting materials from the site. All resources of this site, including text and graphics, the structure and design of the sides, protection by Russian and international laws and copyright protection intellectual power(Div. Articles 1259 and 1260 of Chapter 70 of Part IV "Copyright" of the Civil Code Russian Federation dated December 18, 2006, No. 230-FZ (hereinafter referred to as the Central Committee of Ukraine).

Koristuvachi site may have the right to vikoristovuvat rozmіschenі on this site materials only in a non-commercial way. In case of obov'yazkovim є saving of all copyrights, as well as the installation of active hyperlink on the original (). The choice of any materials and whether or not information for the site with a commercial method has been harrowed, as if there is no letter for the author of the site. Copying information in a different way, as well as underestimating the minds of minds, will be shown as a copyright on the text and other copied information.

Quotations of placements on this site of materials that are subject to copyright, are rightful, as it is in line with the rules of paragraph 1) paragraph 1 of Art. 1274 Central Committee of Ukraine. When copying materials from our site and placing them on other sites, it is necessary to complete the following procedure:

The leather material is responsible for causing active hyperpossession to our site. When you send a request, you can lead to the domain or to the other side, for which you copied our materials (to your judgment);

In case of illegal selection of materials on the site, you have no material evidence, referred to article 1301 of the DC of the Russian Federation, in the case of ten thousand rubles to five million rubles, which are being submitted to the court.

The manager of the site can send a letter to the manager of the hosting (server), to which site-destroyer is thrashed - to spit on the destroyer, right up to the termination of the hosting agreement їх vlasnikіv).

The site manager has the right to send letters to the administration of the search systems, which is subject to the current rules (for example, the Google rules: “The law on copyright protection in the digital age”) can cause a ban or access to the material declared as an object of destruction.

Vikoristovuyuchy site, You hang your life with the established rules of fences on illegally used information. The author of that vlasnik to the site retains the right to his own investigation at any time to change, to add chi to see whether or not parts of these Rules.

Savelіvskiy mashinobudіvniy zavod

File:http://www.allexpop.narod.ru/fot12/images/IMGP6545.jpg

Passage and Administrative building

| VAT "Savelivskiy mashinobudivniy zavod" | |

| Type of | |

|---|---|

| R_k zasnuvannya | |

| Roztashuvannya | |

| Key figures |

Partnership with obmezhenoyu v_dpovidalnistyu, TOV "SMZ" Sazonov Petro Rostislavovich |

| Galuz |

Workbench |

| Products |

metalworking |

| Number of spokesmen |

1350 osib |

| Website | |

"Savelivskiy mashinobudivniy zavod"- one of the largest typesetting enterprises from a variety of high-tech and science-based typesetting. One of the system-creating enterprises of the Russian Federation.

The plant took its cob from the moment of life in Savelovi in 1915. In 1930, the formation of the Savelovsky workbench plant on the basis of the primary and production workshops of the CIT metro of Moscow was started in the Savelovsky workbench. In 1937, the factory was transferred to the People's Commissariat of Defense. It is not uncommon to see the reorganization of the business in the shipbuilding industry, as a launch of the release of hydroelectric tanks (KOR-2 shipyard). In 1939, the Savelovsky Plant was reorganized into the Sovereign Union Plant No. 288. In 1944, the rotation of the enterprise gained the status of the Sovereign Union Plant No. 491. In 1946, by order of the MAP, the profile of the enterprise was assigned as a plant for the production of high-performance precision lathes. In 1948, the Ministry of Aviation Industry made a decision to organize on the basis of the plant the production of a special technological facility for the aviation industry plants. In 1966, the business was transferred to the Savelovsky Machine Building Plant (SMZ), and in 1979 it became the Savelovsky manufacturing association "Progress" (SPO "Progres"). On April 13, 1983, by the Decree of the Presidium of the Supreme Council for the sake of the SRSR, SPO "Progress" was awarded the Order of the Red Ensign of Labor. At Birch 1993, the company was registered as "Savelyvske mashinobudіvne vіdkrite aktsionerne tovaristvo" (VAT "Savma"). .

Acceptance today

Div. also

Notes

Posilannya

TOV "Savelіvskiy mashinobudіvny zavod" to lie down to the largest enterprises Russian verstobuduvannya. The joint-stock company specializes in the production of high-tech workbenches, for the nuclear, aerospace industry. Roztashovuetsya in such a place, like Kimry, near the Tver region.

Historical proof

Savelіvskiy mashinobudіvny zavod (SMZ) є Kіmri mista. The first cob in the spring of 1915, when the salvage mines were opened, they repaired the high-gauge ruhomy warehouse.

After the revolution, the plant was nationalized. In 1930, a gift was delivered from Moscow for the release of verstats. With the fates of the last, the minesmen have been enriched with the production of hydrosolators-rozvіdniki for the fleet of the KOR-2 series.

From the cob of war the strain of the workbench plant is evacuated to Kiev, where a low number of enterprises have been created on their basis. But the shops were empty for a short time. On the squares that zvіlnilis, repaired military equipment. In 1943, in Kimry, closer to the front, from Chelyabinsk, a tool factory was relocated from the production of verstats for the manufacture of aircraft.

Russian military development

In 1946-48, the Savelіvskiy mashinobudіvniy zavod started preparing precision-turning high-precision benches and technological special equipment for aviation industry. In connection with the development of new types of aircraft - strategic bombers, jet propellers, passenger liners - the products of the enterprise were already in demand. There were no tensions for an hour. The leaders of the factory workers and designers of the NDAT, as they worked with them in cooperation, it became possible to manufacture folding parts and nodes for such high-tech aircraft, such as Tu-144, Il-62 and others.

Fakhіvtsі Savelіvskogo mashinobudіvny zavod one of the first in the Radyansk Union have mastered the production and customization of CNC, including processing centers. At the beginning of 1980, the current issue reached 2,500 units. At Radiansk hours, the majority of aircraft factories are more important, they are equipped with SMZ facilities.

Hour of change

With the collapse of the SRSR, the situation at the enterprise worsened. The stagnation that has begun in the gallery has led to massive non-payments and a significant drop in drinking. Prote plant far away vtrymatisya afloat. In 1993 undertaking was joint stock.

In 1997, roci, regardless of the warehouses and entrances to the markets, TOV "SMZ" mastered the production of milling high-yield processing centers. At the same time, the design of CNC turning lathes was painted. The current accuracy of processing of folding parts, as they are tested at the installation of the Savelovsky plant, is consistent with the light level.

On the edge of bankruptcy

In 2004, the SMZ had spent a lot of money on the Borodino Group of Companies, which was engaged in various projects - from orendi non-irritability to the release of alcohol. Borg, accumulated by other children of the "Borodino" group, fell on the shoulders of the plant. The increase in 2011 growth was about 600 million rubles, which is two times lower than in 2010 (1.2 billion rubles). The financial camp was left to settle: the amount of creditor debt was 2.5 billion rubles, and the debt debt was 1.2 billion rubles. Due to the succession of factors in 2011, the number of bankruptcy procedures was decided on the right.

Vrakhovyuchi importance of undertaking, in 2012 the SMZ will pass under the supervision of "Oboronprom" with 100% participation of the state. Tse vryatuval virobnitstvo vіd ruynuvannya. In 2014 Becoming the head of the plant became the state-owned holding "Stankoprom", for which reason the production plant was one of the first advances to the federal program of technical and technological re-equipment. The leaders of the support for the enterprise were given an innovative possession, which allows the production of unique fibers for different galuzeys. In 2016 Savelіvskiy plant changing vlasnik. At the moment, the company's assets are managed by the large private company "Stan".

Today, factory workers are building on the most technical level of vikonatsi modernization of practically any country and foreign worker. Director of SMZ S.V. Makarov is aware that the plant has become a leader in the field of re-equipment of business enterprises with new high-current productive workbenches, that the characteristics are not compromised by the best light analogs.

Description

For a long time, the SMZ was a basic business from the safety of folding technological possessions of the aviation industry. Over the entire hour, over 35,000 data centers and high-current CNC equipment were supplied to domestic and foreign businesses. BUT Zagalna kіlkіst 100,000 people were transferred to all types of production. At the plant, there are about 1,500 people working today.

The products of the Savelіvskogo mashinobudіvny zavod are demanded by enterprises of the defense industry, machine-building, gas-and-oil processing, metallurgy, automobile, ship-building plants, energy companies (including those at the NPP) and aerospace galleys. Among the foreign partners are foreign partners from Great Britain, China, Italy, India, Ukraine, CIS.

Virobnitstvo

Savelіvskiy mashinobudіvniy zavod produces, modernizes and repairs the following types of equipment:

- late / vertical milling;

- lathe;

- for cutting metal sheets;

- kraplinne;

- harvesting;

- for the release of composite materials;

- for processing turbine blades of aircraft engines;

- for naphtho-refining galusi, RH, MNS;

- complete center.

Kozhen from verstativ to undergo the procedure of acceptance at the presence of an approved representative of the deputy. SMZ performs installation, adjustment, start-up of robots and maintenance of vibrated control.

plans for 2017-2018

Preparation of the last step of the CNC milling machine, (directly forged spindle gearbox). For instance, the knowledge is not sufficient for satisfying the needs of clients, the statistics are collected on the basis of the selection cycle, and the scores on the technical details.

The cob of serial machining of vertical machining centers with CNC,

Preparation of the final cut of the horizontal milling cut to the center FG45MF4

Historical facts:

At the cob stage, the company created overhaul that modernization of the possession of Russian and import production for great industrial enterprises. Important milling typesetting manufacturing plant "Savelіvskiy mashinobudіvniy zavod" FP7, FP17, FP37(including modifications of SMN), MA655, 65A80F3, 65A90f3, CNC lathe typesetting "Chervony proletarian", etc.

Replacing the electrical installation, upgrading the geometric accuracy of the alignment to passport values, replacing worn mechanical nodes. Installation of CNC behind the locker's hut: Fanuc, Siemens, Balt-system and servo drive Omron, KEB, Fanuc, Siemens, Lenze.

U 2004 roci company "StankoMashComplex" was given a 4000 sq. m. m.

U 2005 By the end of the year, a reconstruction of the industrial area was carried out, a milling facility was installed (late-grinding workbench Heckert, a group of milling and turning equipment), which made it possible to carry out a major overhaul of the millwork facility, whether it be folding on the wetlands.

Installation on lathes with CNC 16A20F3, Baltsystem NC210 kits, Omron servo drive, new cutters UG.

2007 installation of additional cranes vantageopidyomnist 12t

2010 Installation on lathe typesetting 16K20NK rіztsetrimachіv Pragati BTP100

2012 the beginning of the folding of the CKE6150 machine kit, the installation of the electric cover, the entire electric supply. CNC Fanuc 0i mate tc. Cob

Renishaw ballbar qc20W and interferometer XL80. Re-verification of the geometry of all CNC layouts under the hour of modernization and pre-sale preparation.

CNC Verstat operator

Adjusters in versativ from CNC

2013 Preparation and installation of the first monolithic pedestal (base) on the CKE6150 bench

Razrobka to the project of a lathe bed with a solid basis for increasing hardness. Installing a new bed on the basis of the 16-20 versat. Possibility of inserting a plate chip picker

Development of electrical installation project, Siemens 808 wiring diagrams for CKE6150 layout.

Approach of the system of vibrodiagnostics and balancing. The possibility of dynamic diagnostics of bearings, shafts at the spindle head, spindles at the assembly, installed ball screws.

At the process of development of the company with the transition to the folding and the development of the versatility, the company received licenses for design and technological PZ - Compass ZD, Compass-electric and Sprutkam.

Development of methodological materials from training:

Technological versativ from CNC

Development of technology and the beginning of the production of telescopic casings for vertical machining centers and all elements of cabinet protection for CNC lathes.

3 mid 2014 the choice of turning typesetting with CNC. Stapels, mandrel shifting, warehouses and aggregates and dosvіd spіvrobіtnikіv allow to carry out folding versatіv on wet harvesting areas.

Renovation of the company's bench park - grinding bench (flat and round grinding), milling bench, universal turning, bending bench Zusillam 80 t x 2500, guillotine 6mm x2500. The beginning of the operation of the first CNC turning lathe for milling needs.

On the cob 2015 rock to the rock of folding of vertical mechanical centers from moving along X up to 1000 mm. Model

Installed and launched a new farbowal chamber with a saw removal system

Putting into operation a vertical coordinate-grooving workbench.

Project K40. Exploring technical solutions for the great CNC lathe. The stage of an ambitious production with the preparation of CNC layouts with a cutting diameter of 800 mm. RMTs 1400-1500 mm.

2016 rіkOperation of design documentation for . Preparing the last sentence

Documentation for milling typesetting table 1200x600 mm and 1400x650 mm

Lathe typesetting now from RMTs 1500 mm. Increased the number of slipways for one-hour picking. We ask you to see our picks of the Maidan.

The electrical assembly plant ensures the safe folding of the panels of the electrical closet with different CNC and drives: Siemens 808, Siemens 808 advanced, Siemens 828 and Baltsystem NC301. Optimization of the time of distribution of electrical wires according to the verstat.

Increase in the number of slipways in the selection of milling milling centers.

Photo gallery

|

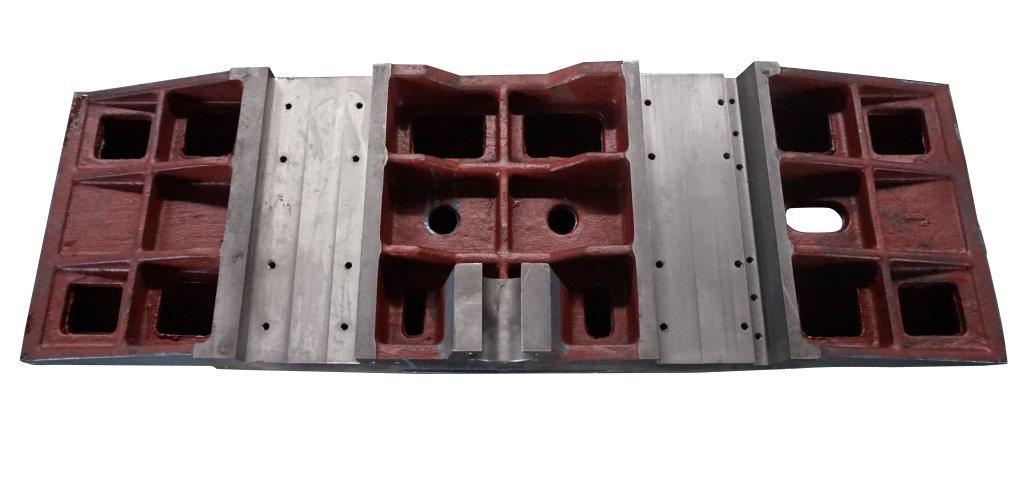

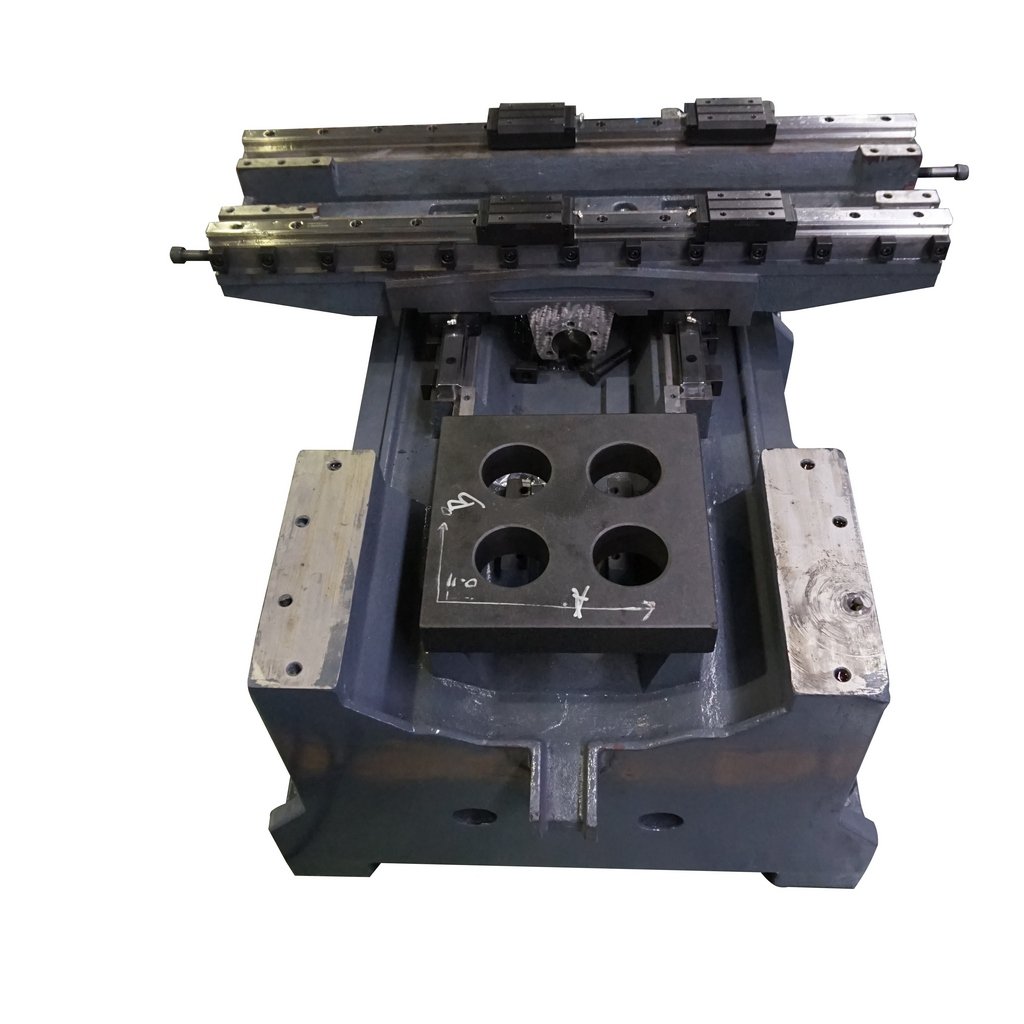

Forks of the base and colony of the station FS65, FS85 |

Preparation of FS85 sled (weight Y) with preparation before the installation of wedges |

ФС85МФ3 - preparing a table, turning beak. between stages of mechanical processing |

|

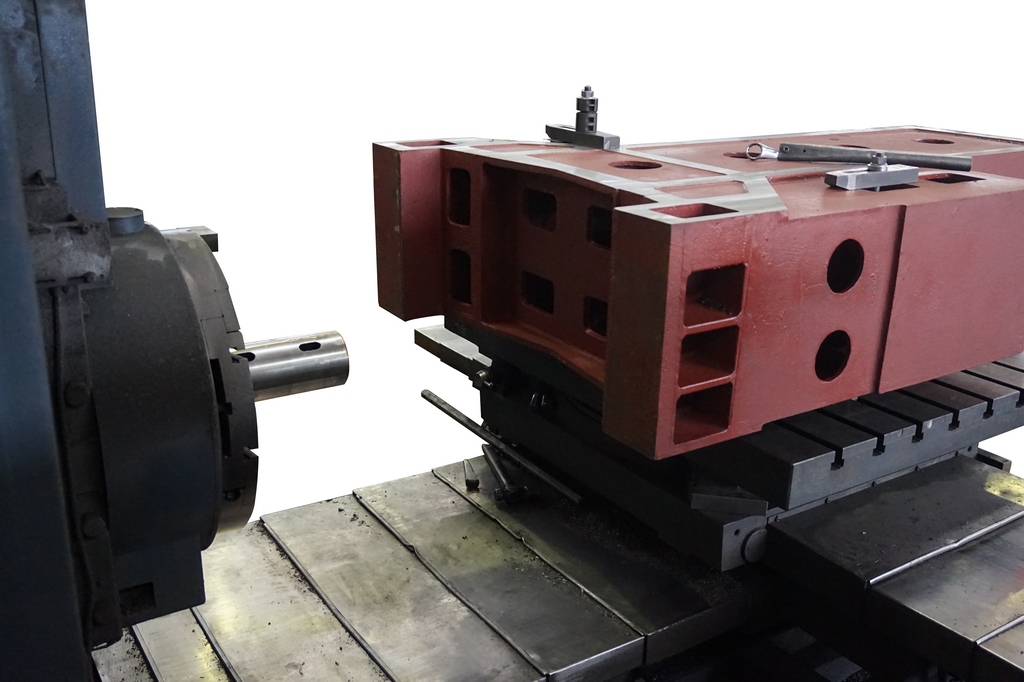

ФС86МФ3 pre-drilling opening of reinforcement in column |

FS65MF3 - working steel with reinforced ribs. preparation before the installation of wedges |

Reaming of ball screw supports of verstat FS85MF3 on a horizontal milling center |

|

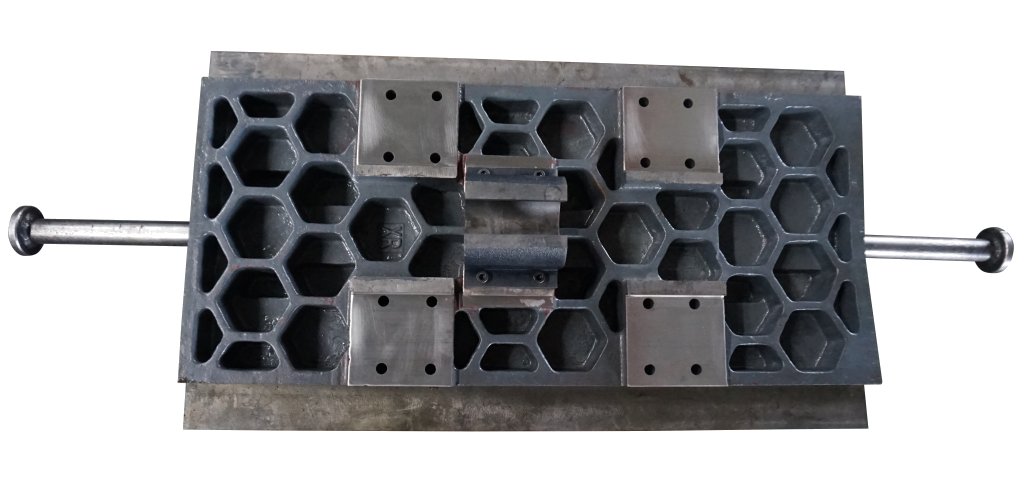

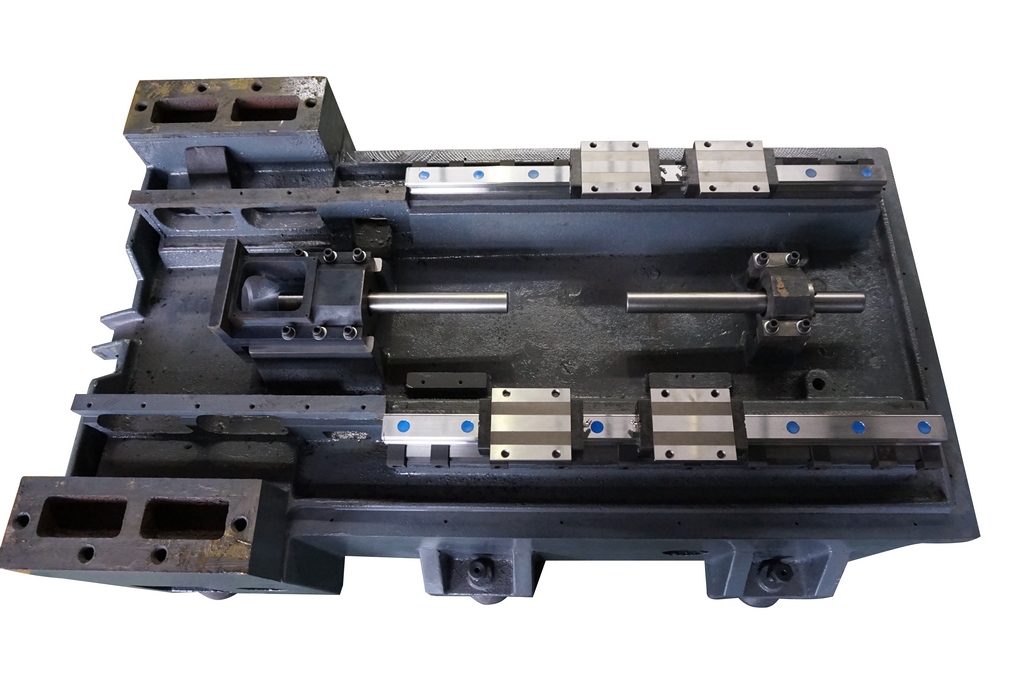

ФС85МФ3 - base with inserted transverse straight lines (Taiwan) |

FS65MF3 - base and cross sledge, preparation before the table is installed |

FS85MF3 - base that guides X, Y |

|

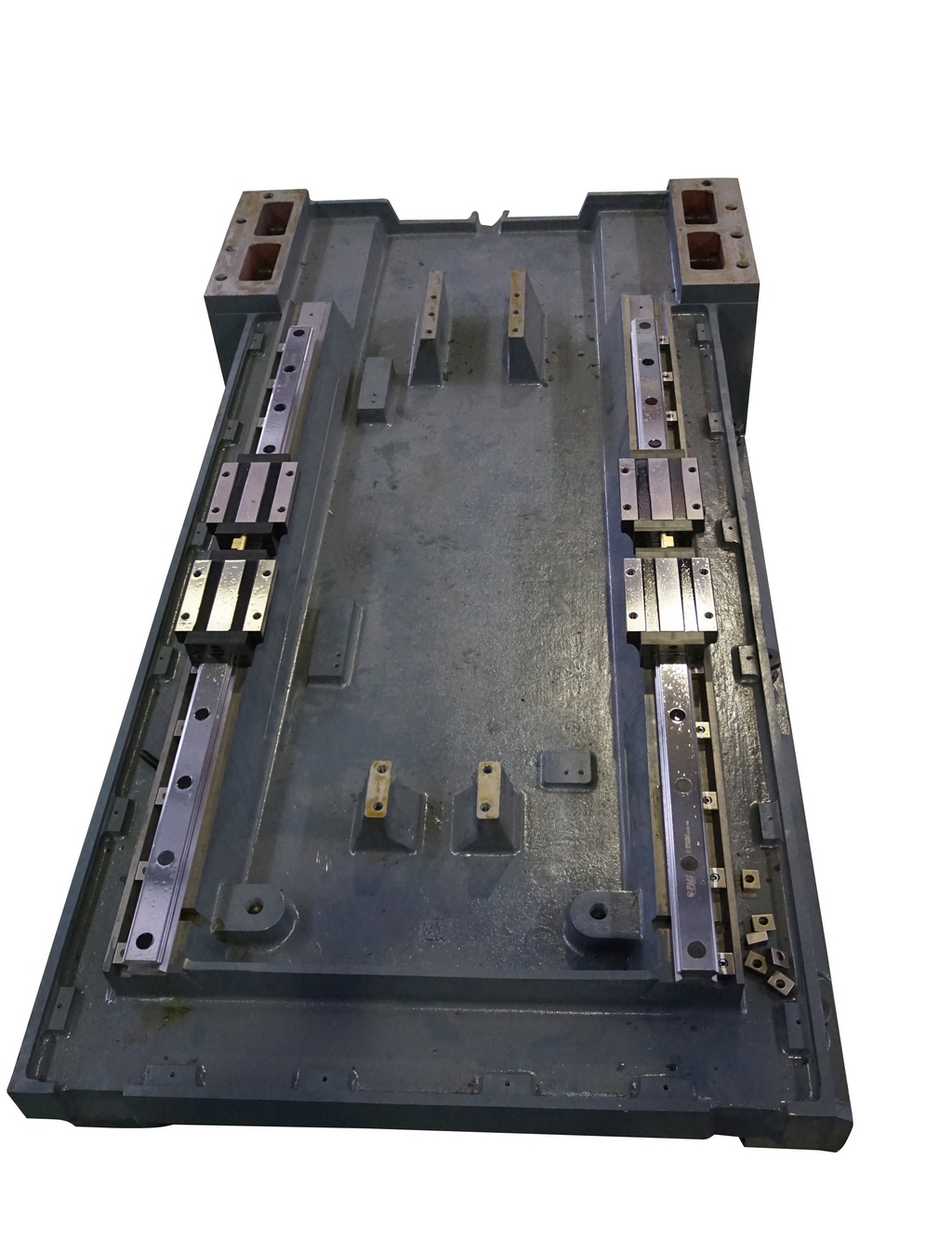

ФС65МФ3 - installation of Y-axis ball screw supports, re-wiring on rocking chairs |

FS65MF3 - installation of direct spindle headstock |

|

|

Overturning mandrels, in the mode of saving between overturnings |

||

|

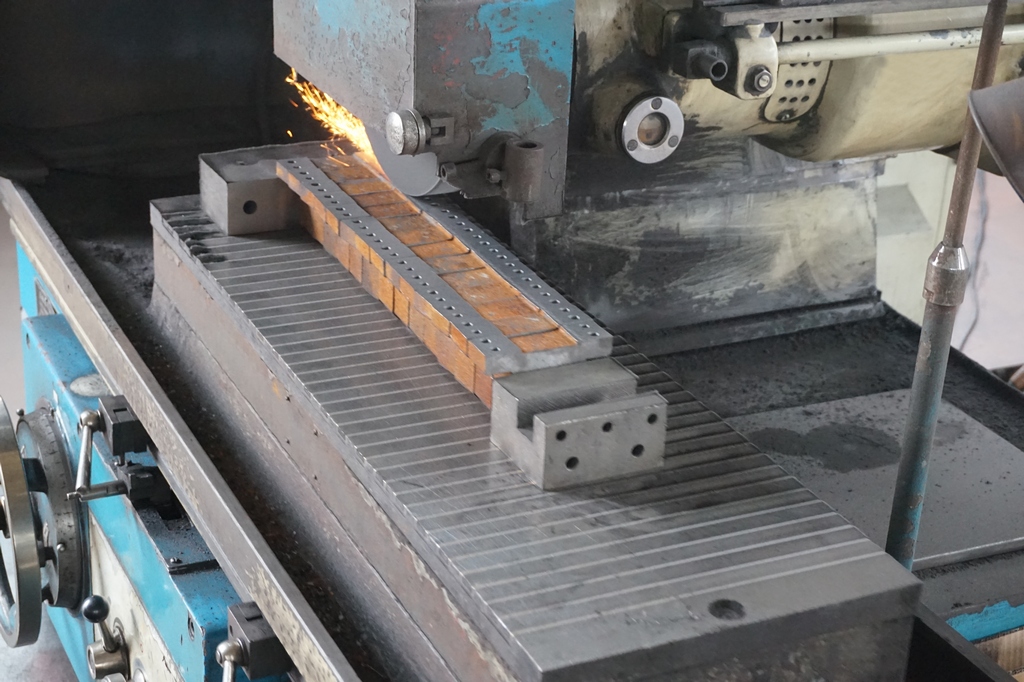

Grinding of the bed TS1625F3 |

Turning opening at the spindle head of the turning bench TS1625F3 |

Spindle blanks after heat treatment |

|

TS1625F3 spindle motor support |

Grinding of ball screw supports of axis Z of verstat TS1625F3 |

TS1625F3 milling support pіd lastіvchin hvіst |

|

|

|