Ulyanovsk verstobudivny plant. Ulyanovsk workbench plant DMG MORI

For example, spring 2015 at the metro station Ulyanovsk came to the tract of the Ulyanovsk verstobudivny plant DMG MORI. To the guests, we will ask for the approval of a new brewing complex, we will present the workshops, possessed of the rest of the technology. At the moment, the Ulyanovsk plant, with the help of technical equipment, overhauls all the undertakings of the DMG MORI company.

|

For example, the year 2012 was a sign of laying the first stone on the territory of future life, for example, the year 2014 was visited at the Richtfest festival organized by DMGMORI in Ulyanovsk in commemoration of the tribute to the future plant. At the same time, the DMG MORI plant in Ulyanovsk is going to be equipped with a molding maidanchik, ready for the release of metal molding for Russian enterprises. As a result, the plant was allowed to localize the production of high-tech equipment in Russia and for Russia. 14 high-tech workshops of the ECOLINE series were presented at the technology center of the new plant. Kerіvnitstvo to the plant pragne replacement of part of the component parts of the Russian manufacturing industry. It is planned that by 2019 the localization will be 50%. So far, over 150 DMGMORI layouts have been produced in Russia. In the future, it is planned to issue 1000 versions per river. Also, at the Ulyanovsk plant, a new model of the workbench is being developed.

The warehouse area of the new plant is 3,000 sq.m. Ulyanovsk plant DMG MORI has a staff of 200 spivrobitnikіv and vlasne vyrobnannya with a maximum number of virobnichny years is close to 22500. Ulyanovsk workbench plant DMG MORI may be a vlasny Technological center with a total area of 640 sq. m. In addition, the entrepreneurs of the enterprise are expanding the solutions for the key in the field of aerospace industry, automotive industry and medicine. The Technological Center also gives encouragement to the patrons and promotes a wide training in the halls of programming, improvement, operation and maintenance of all types. The presence of the Park of energy solutions allows the Ulyanovsk Verstatobudivny Plant to cover up to 15% of its energy consumption from the rapid generation of CO2 by 108 tons per river.

Under the hour of the tour of the plant, we were able to talk to the plant's spokesmen. Next, the warehouse for the staff of the enterprise is made up of young fahivtsiv. We have trained literate highly qualified engineers, who have completed a course in manufacturing. Important criteria for the acceptance of practice and knowledge foreign movie. DMG MORI also attaches great respect to the spivpratsi z local higher education institutions and may own the Training Academy. It is not so easy to spend on undertakings, being a student of a faculty, you can demonstrate your ability and ability to work on undertakings of a high technological level. Children go through a low test, and for pіdbags they can be proponated by a robot.

The very undertaking is a complex of workshops, the skin function has a unique function.

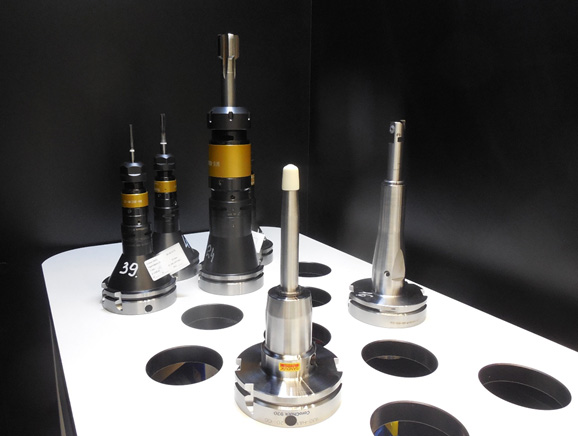

Instrumental virobnitstvo

Warehouse shop and mechanical processing shop

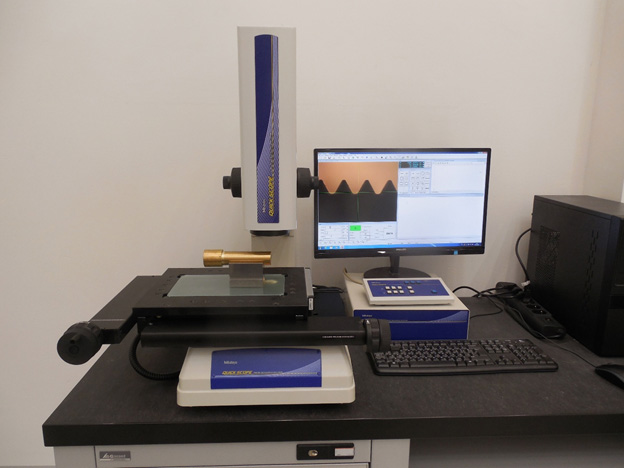

Vimiryuvalna laboratory, in which vimiryuvannya of finished parts of the workforce is being tested, that re-verification for compliance with their standards. Also here we see the world of test blanks, processed on new workbenches. Usі protocols vimirіv nadayutsya zamovnik - the purchase of the verstat

Warehouse facilities with automatic tool cabinets

Farbuvalny shop

Also, partners of the DMG MORI company were requested for consideration - representatives of the maker of components for versativ, such as the company HORN - the maker of the verstat tool, the company Renishaw, Siemens and many others.

Within the framework of the business program at the Ulyanovsk verstatobudivny zavod, thematic seminars were held for industrialists on the topic of automation of production, the acquisition of DMGMORI on the premises of aerospace galuzi and other galuzy, which is in charge of hi-technological production. The program also has a seminar

CELOS ® systems - the core interface is as simple and easy to use as a smartphone. Behind the help of a unique 21.5” touchscreen display with MultiTouch CELOS® technology, it allows you to visualize, document and visualize the task, process that performance characteristics.

Vіdkrittya plant in Ulyanovsk yelled even yaskraviy resonance in rosіyskih business kolakh. The project of life and work for the plant is actively supported by the administration of the place. At the Ulyanovsk DMGMORI plant, new Russian technologies are being born this year, building Russian manufacturing enterprises at the current technological level, giving them a new high-technological possession, virobleny in Russia and Russia.

*Material prepared by Voitsekhivska Elizaveta

Plant Ulyanovsk plant of important and unique production lines, known to the people like UZTS, if it is one of the industrial flagships of the Ulyanovsk region. The plant's products were widely victorious on the folding forgings of the Radyansk clocks. A large part of the brewers at the manufacturing plant was exported, which brought good income to the country. Prote kіlka rokіv verstatobudіvniy zavod has ceased to operate.

Why did it all start

In the distant 1946, after the end of the war, after the end of the war, if the country was actually rebuilt, the radyansky detachment praised the decision about life in the Ulyanovsk verstatobudivny plant. Irrespective of the great number of otrimanih for the reparation of high and precise German versatility, industry, which is reborn from the ashes, more and more versativ is required. Verstativ important, great and unique. Such versativ, yakі treba would be, build on the foundations, verstatіv, for a long time, such were the workshops.

One of the poorest factories, building workers, and designing it, having become UZTS. In 1951, the factory was turned into a life, practically overnight, a residential microdistrict was laid there for the workers of the factory. Before the beginning of life, foxes and swamps were known at the plant, the mistresses went there to beat the pitching of that hare, often elk came into the woods - the head of an elk became the emblem of the plant.

Budіvnitstvo was completed in record terms, and already in 1956 the plant began to function. Until the 1970s, UZTS mastered the production of CNC machining, and in the 1980s, they mastered casting and special alloys, and the pace of production of flooring grew, so that the plant was transferred to other places for expansion.

Vcheniy Yunak

A great role in the establishment of the plant was played by Ignaty Yunak-Shanyavsky. Naschadok of a noble family, having graduated from only two classes of a gymnasium, if the Zhovtnev revolution lulled. Having obtained home lighting, Ignaty began to work for 14 years. On the back of a shepherd, then smashed to the factory of colorful olives, from the beginning of the rokiv virіs vіd robіtnik to tekhnіchny kerіvnik. Self-sustaining armchairs, having entered the Leningrad Metallurgical Plant as an armchair, and already for the river having taken over the designer's seat.

So, without having obtained any higher, or medium-specialized education, Yunak-Shanyavsky designed the first important turning carousel workbench for the Radyansky Union. Being a talented designer, he was very young to high estates, and in 1953 he took the head of the special design bureau at UZTS, and worked until the very moment he retired. It is up to the very pen to lay down practically all the drafting projects that are being developed at the UZTS. Until his death in 1999, Yunak-Shanyavsky gradually took a part in the life of the plant, periodically embracing the planting of the director's intercessor, helping the SKB robot. Having trained and trained a whole cohort of engineers, the deacons of them graduate from universities at their higher levels.

plant at once

For 40 years, the plant has been turning great machines, building with micron accuracy, turning bagatometric details, or sharpening one workpiece with a cut of rich top-surface boudinok. Without UZTS, there would be no atomic water bodies and reactors, there would be no benefits for space, that strongest army in the world, a peaceful sky over the head of that Radian auto industry.

Right up to the 90s of the twentieth century, the plant pulled ahead of the economy of the region, and after the collapse of the Radian Union for a long time, having continued to release products for UAZ and VAZ, as well as zdіysnyuvav in-line repair of that production, which was produced for radian hours. Ale z nastannya nil'ovykh plant has changed into a sbitkovo enterprise. Until 2011, UZTS stopped operating.

Alfa-Bank's call center, a few other offices and warehouses, were placed on the ruins of the Leviathan. Truth be told, they couldn’t “drive in” the UZTS to the authorities of the radio lamp plant. At the same time, a couple of workshops that have been left behind already have two subsidiaries: TOV "Ulyaniv Plant of Important and Unique Verstativs" and TOV "Simbirskiy Verstatobudivny Zavod". Prote the scale of their variability is inconsistent with the enormous magnitude of the UZTS.

Yesterday at the industrial zone "Zavolzhya" the official

acknowledgment of the German-Japanese plant DMG Mori, the most recent

It's quiet to enter the company's warehouse. The slogan of the plant is “Zrobleno in Russia

and for Russia".

Investment opportunity between DMG Mori

(before

- GILDEMEISTER), by region and development corporation

Ulyanovsk region was signed on 16 November 2011.

Budіvnytstvo rose at the dawn of 2012. First 25 spivrobitnikiv

The plant was started on the basis of the Polish subsidiary Famot.

The idea was voiced for a training center at UlSTU and UlDU. General

director of TOV "Ulyanivskiy verstobudivny zavod" - Oleksiy

Antipin. The amount of investment is 70 million euros. 18 black 2014 rock

vypustiv first verstati (total potim - 100), yakі

were taken to the Ulyanovsk nanocenter, which is also located in the Zavolzhya industrial zone. Tse universal turning bench

CTX 310 ecoline and vertical fittings

centrifuge DMC 635 V ecoline / DMC 1035

V ecoline and universal milling bench DMU

50 Ecoline.

Coming soon will be the placement of mystical prayers for all kinds

from sheet metal. Zreshtoy, more operations from mechanical work are carried out by self-tightening, with a rich view of details from the post-workers. The type of postal workers in Russia is also limited to electric parts for

versativ, casting, spindle modules, tool system.

The main folding in localization - electronics, language, swedish

in total, let's talk about 3D control technology for a unique

programming and simulation with SIEMENS 840D solutionline.

Representatives of DMG Mori found out that it is still important to know

zavdannya, but the work of this sphere is carried out, for example, from Moscow

Sovereign Technical University named after M.M.

E. Bauman. Zagalny vіdsotok localіzatsії infections - 50%.

New DMG Mori announces localization of production

possessing the highest quality under the motto "For Russia and for

Russia”, and focusing on verstas of the Ecoline series.

sold for DMG Mori models CTX 310 ecoline - 7

million 299 thousand rubles, moreover, packaging, installation and training

work at the verstat is not included in the price. Truth, transferred leasing

for 36 months with an advance payment of 30% of the wage rate. Є

versat that for 9 million 599 thousand rubles, the same model DMC 1035 V ecoline.

The parameters of the new plant are as follows: land plot with an area of 200

thousand sq. meters, forget the area - 21 thousand square meters. meters,

warehouse workshop - 3,300 sq. meters, virobnicha

pressure - 1200 worksheets per workday when working in one shift.

The number of spivrobitniks in Russia is 200 osib. DMG Mori Prop

solution "key" for aviation (turbine blades, casings,

shasi, blisk), space, automotive (bearing bearings,

rolling tools, clutch housings, details

galm), medical (suglobi with titanium, other alloys)

galuzey, as well as machine-building (press-forms). Regions

sales and service - 5, є pіdtrimka 11 dealerships

centric

The plant has its own Energy Solutions Park,

which covers 11% of business expenses, plans to withdraw by 15%. 280 thousand kWh/year of energy coming out of the savings system

solar energy and wind CellCube, sony batteries SunCarrier and wind turbines WindCarrier. Three eGolf cars at the factory

“live” with energy from the eCube system, 100% environmentally friendly

clean car park.

Andriy Belov

Our conclusion:

In 2009, the roci rose to spivrobitnitstvo between the German GILDEMEISTER and the Japanese Mori Seiki. In 2011, after two successful projects,

Mori Seiki becomes the owner of 20.1% of the shares of the right

vote in the GILDEMEISTER concern, the same GILDEMEISTER becomes

the largest shareholder of Mori Seiki, for a share of 5.1% of the shares.

For two milestones for the implementation of a strategic partnership

GILDEMEISTER Aktiengesellschaft and Mori Seiki Co. Ltd. signed

Please about spіvpratsyu.

2014 DMG MORI opens new head office in Tokyo,

global sales and service network DMG MORI

coordinated by head offices at Winterthur and Tokyo. in the spring

2015 DMG MORI CO., LTD. become a volunteer 52.54% of the shares,

and the process of angering the companies has been completed.

The acceptance of practice in the sphere of production and the supply of verstary possession is carried out here to expand its base and manufactured products, in order to increase the quality of industrial production. Here are the backs of the country, as well as the foreigners, and the lines of foreigners.

Ulyanovsk verstatobudivny plant ensures the active development of industry in the region, the workers of the Ulyanovsk region are the most advanced in this sense. The main pillar of virobnitstva is the well-oprated infrastructure and the base of the above-mentioned post-employees in the Yaksnoy syroviny.

At the technological center of the enterprise, the development of thoroughly developed equipment is carried out. DMGMORI Ulyanovsk Manufacture Plant may have foreign investments in its assets, which will increase the efficiency of development.

The business can be handy for distribution, the shards of wines are close to potential customers. At the same time, the development of both a universal turning bench and a hard vertical milling center is being carried out. Plans are being made for the distribution of mystical designs, which are to be made from sheet metal.

Basic virobnizvodstvo

The main direct detail, as zdіysnyuє TOV "Ulyanovsk verstobudіvniy zavod", є vysochennya high technologies and science-based projects, yakі zmozhut zdіisniti more import substitution on vіtchiznyany product.

Jointly with Italian partners, crafts and robots are created, yakі zmozhut zvaryuvannyam large-sized metal structures. Here, high-quality layouts are made, as well as new fully developed knots and mechanisms for them. A lot of respect is attached to the methods of control over the robotic mechanisms.

Main helpers

The products are delivered to customers in the nearest regions, as well as other points of the edge. Remembrance to work undertakings, as if they would require modern technical equipment of a high level. Simbіrskiy verstobudіvniy zavod Ulyanovsk specializes in high-current installation, which is relevant for many modern technical areas.

Export

Acts of distribution are delivered overseas, especially those that are created together with overseas partners.

Products

The products that the Ulyanovsk Plant manufactures important and unique production lines, may have a few modifications in its model range, so there are still a few additional, with smaller parameters, up to the basic skin model of the skin type.

|

Type of versat |

|

|

Vertical milling machine with numerical control and cross table |

|

|

Universal vertical milling machine |

|

|

Universal post-milling machine |

|

|

Turning post-milling with numerical programmable cutting |

|

|

frazernium |

|

|

Obrobny center |

|

|

Turning and carousel |

|

|

Universal turning-guintorizny |

|

|

heavy lathe |

|

|

Horizontal-grooving |

|

|

Special for processing of kolіnchastih valіv |

|

|

Heavy planer |

7228 (NZTGG) |

|

Wheel-turning |

Services

Here you can call on services from additional mechanical processing, such as including a complex of various works, such as calling to give the robots the necessary parameters.

Main types here is:

- Turning work, where to enter the internal surfaces to the required size, cutting and trimming chamfers, making grooves. Roztochuvalni robots serve for the processing of deaf openings. Grinding robots ensure surface finishing to the required standard.

- Dentistry works to help create the gears of the mechanism for changing the parameters, to find those, there are none in the serial production.

- Milling cutter is used on universal milling benches and s її additionally, the ends and ends of the virobs are more important.

- Zvaryuvalnі roboti - zdіysnyuєtsya vzdіysnyuєtsya vzdіysnyuєtsya vzdіysnyuєtsya vzdіysnyuєє zvaryuvannya zvaryuvannya zvіbnіh nіtіnіh, scho vdіyskyuєtsya vzdіysnyuєє stvennya metalevіh konstruktsіy z parts zamovnika zvaryuvannya vіbnіhnyh scho, scho go to ustatkuvannya, scho ekspluatutєєєєєє.

- Rіzannya metal - rasdіlyaє workpiece zgіdno z given dimensions for an additional knife or guillotine. Also vikorisovuyutsya typing for plasma cut metal.

- Thermal processing– allows you to change the structure of steel by heating and cooling.